Field-replaceable motor stator provides dramatically improved uptime Time-proven reliable Oil-Free two stage airend Ultracoat Solving the need for better oil-free performance and energy savings Unequaled efficiency and reliability saves energy

Only Ingersoll Rand offers Nirvana Rotary Oil-Free, the world's first true variable speed oil-free screw air compressors for critical oil-free applications requiring the highest quality of air and the greatest reliability available on the market. By matching an innovative modular variable speed inverter with a HYBRID PERMANENT MAGNET® motor, Ingersoll Rand is again first-to-market, this time with a true variable-speed drive, rotary oil-free screw air compressors. The two-stage Nirvana Rotary Oil-Free screw air compressors has fewer rotating parts than any other rotary srew air compressors in its class, And the HPM® motor driving the Nirvana Oil-Free raises the standard on compressor reliability to an unequaled level. There are no motor bearings in the HPM® motor. And since the HPM® motor directly drives the compressor, there are no pulleys, belts or couplings to wear out, leak or need replacing. And there is nothing to get out of alignment. Coupled with Ingersoll Rand's time-proven, reliable two-stage oil-free airend, Nirvana Rotary Oil-Free screw air compressors is as reliable as an air compressor can get.

The challenge: to give our customers an oil-free rotary compressors that operates at peak performance throughout its lifetime. With the introduction of our fixed speed oil-free compressor, SIERRA, we introduced UltraCoat. After 10 years of superior performance and peak performance in real world applications, UltraCoat has proven to be unmatched in its performance.

We use UltraCoat to protect every SIERRA airend and now every NIRVANA Rotary Oil-Free airend. Ingersoll Rand's exclusive UltraCoat rotor and housing coating process uses a mechanical and chemical bond to insure the thinnest coating with the tightest possible grip, First, the rotor and housing surfaces are mechanically prepared to accept the coating. Then UltraCoat is precision-applied to insure the most even coat possible. Finally, all surfaces are heat-cured to solidify the mechanical/chemical bond. Compared to other coatings, UltraCoat delivers longer life and 10% energy savings. To help our customers get the best performance, we didn't limit our design efforts to the coating. We selected stainless steel and aluminum for the piping linking the intercooler with the stainless steel second-stage rotors. Condensation created in the cooling process cannot corrode these materials, eliminating the possibility of rust formation and carry through, further lengthening the life of the coating and rotors. Design innovations such as this and Ultracoat is what separates Nirvana Oil-Free from any other compressor in its class. Surface preparation creates minute crevices in our rotors and housing that tightly grip the ultracoat coating. The result is the most durable performance on the market, lowering our customers' energy costs and increasing the life of the airend in their nirvana rotary oil-free screw compressors.

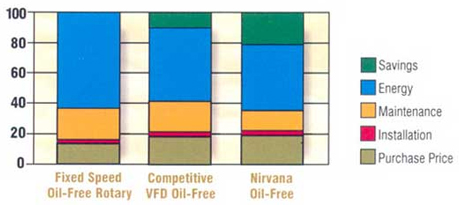

Comparison at 70% average volume capacity; 4,000 hours per year; .05/kWh Comparison at 70% average volume capacity; 4,000 hours per year; .05/kWh Traditional purchase decision factors represent only 20% of the cost to own and operate a rotary screw compressors while energy represents 60% of the life cycle cost. Only nirvana will save at least 30% of the energy cost over its life.

The Nirvana motor turns off at 25% capacity and automatically turns on when air pressure decays. Ingersoll Rand's exclusive VSD makes possible a range of operating characteristics that produce this unequaled energy efficiency. In a conventional air compressor, starting up the motor creates an enormous energy draw, as much as 800% of the full-load normal running current. Nirvana's HPM drive system limits the in-rush current to less than 100%. This significant decrease in starting amp requirements minimizes peak charges, leading to a lower energy bill.

| Model | Free Air Delivery - m3 / min | ||||

| 7.0 bar g | 7.5 bar g | 8.0 bar g | 8.5 bar g | 10.0 bar g | |

| IRN37K-0F | 5.7 | 5.4 | 5.3 | 5.1 | 4.6 |

| IRN45K-0F | 6.7 | 6.7 | 6.4 | 6.2 | 6.2 |

| IRN55K-OF | 9.4 | 9.0 | 8.8 | 8.5 | 7.8 |

| IRN75K-0F | 12.3 | 11.9 | 11.7 | 11.7 | 10.6 |

| IRN90K-OF | 14.8 | 14.4 | 13.8 | 13.4 | 12.1 |

| IRN110K-OF | 18.1 | 18.1 | 17.2 | 16.7 | 15.4 |

| IRN132K-0F | 21.5 | 21.2 | 20.6 | 20.1 | 18.6 |

| IRN160K-OF | 25.5 | 25.4 | 24.5 | 24.1 | 22.8 |